If you choose MWAC Food Plant Sanitation Experts for commercial cleaning in Brampton, you're ensuring your facility meets rigorous HACCP, GMP, and CFIA standards. Their systematic approach includes tailored cleaning protocols, certified detergents, and detailed record-keeping for regulatory audits. Certified professionals utilize state-of-the-art equipment and eco-friendly solutions to enhance compliance and reduce downtime. You get hazard analyses, allergen control, and precision-managed sanitation that maintains your operational integrity. Discover how MWAC's proficiency enhances your facility's compliance and standing.

Core Takeaways

The Importance of Food Facility Cleanliness in Brampton

Even though Brampton's food processing sector depends on efficiency, rigorous sanitation protocols are vital to stop contamination and ensure regulatory compliance. You need to prioritize food safety by implementing strict cleaning schedules, utilizing validated detergents, and verifying all contact surfaces meet CFIA and HACCP standards. Proper hygiene practices—such as routine equipment disassembly, thorough handwashing procedures, and appropriate waste management—minimize microbial risks and copyright product quality. Safety assessments review your facility's implementation of sanitation standards, so keeping detailed records of your cleaning procedures is critical for compliance. Bacterial cross-contact can jeopardize both consumer health and your company's reputation. By enforcing disciplined hygiene practices and monitoring critical control points, you verify your facility consistently delivers safe products while satisfying Brampton's strict industry regulations and safeguarding your operational integrity.

Core Offerings Offered from MWAC Food Plant Hygiene Professionals

When you team up with MWAC Food Plant Sanitation Experts, you're provided with an extensive suite of specialized services structured to align your facility with CFIA, HACCP, and GMP standards. You'll receive personalized sanitation protocols that accommodate your facility's unique operational layout, product lines, and workflow. MWAC's team carries out extensive risk assessments to identify and mitigate contamination sources, cross-contact points, and microbial hazards. They set up detailed cleaning schedules, confirm chemical concentrations, and document each step for audit-ready traceability. You'll also receive support for equipment deep cleaning, environmental monitoring, and allergen control measures. Each protocol follows systematic procedures, guaranteeing you consistently meet regulatory expectations and maintain product integrity. With MWAC, your sanitation program isn't just routine—it's a crucial aspect of operational excellence.

Adherence to Health and Safety Standards

Following through with these specialized sanitation protocols, maintaining regulatory compliance is a key consideration for every food processing plant. It's essential to implement thorough documentation and validation to fulfill industry safety standards, like HACCP, CFIA, and local municipal guidelines. Regular audits, both internal and external, ensure you're consistently aligning cleaning procedures with evolving regulations. Your cleaning personnel must undergo current training on regulatory compliance, highlighting personal protective equipment, chemical handling, and preventing cross-contamination.

You can't afford procedural weaknesses; non-compliance can lead to significant financial penalties, facility closures, or damaged reputation. Through consistent tracking and documentation of hygiene protocols, you establish documented evidence for auditors and business partners. Implementing corrective actions upon discovering issues proves your active adherence to safety requirements while safeguarding your facility's operational integrity and consumer trust.

Advanced Cleaning Protocols for Food Manufacturing Plants

Effective sanitation in food processing facilities relies on multiple specialized cleaning techniques designed for the unique risks of the environment. You'll implement targeted sanitation protocols, such as Clean-in-Place (CIP) systems for equipment that must remain intact, and Clean-out-of-Place (COP) methods for detachable parts. Physical cleaning, high-pressure washing, and foaming agents address stubborn residues, while sanitizing agents eliminate pathogens on contact surfaces. It's critical to create a cleaning frequency schedule based on hazard analysis and risk assessment, guaranteeing you address high-touch and contamination-prone zones more often. Documentation of all procedures ensures regulatory compliance and traceability. By adhering to validated cleaning methods and maintaining strict adherence to established sanitation protocols, you'll prevent cross-contamination, manage allergen exposure, and maintain a safe food processing environment that satisfies industry standards.

The Benefits of Expert Commercial Cleaning Services

Entrusting your facility maintenance to specialized cleaning contractors in Brampton guarantees compliance with stringent industry regulations and optimizes your operational workflow. By delegating sanitation tasks to certified experts, you'll reduce the risk of regulatory violations, product recalls, and cross-contamination incidents. Expert cleaning personnel utilize established procedures and state-of-the-art technology, maintaining pathogen control and allergen removal that surpass industry benchmarks. These services contribute to cost savings by decreasing downtime due to failed inspections and reducing spending on internal staff development, supplies, and equipment maintenance. Additionally, professional cleaning enhances employee wellness by controlling microbial hazards and airborne contaminants, providing tangible health benefits. This forward-thinking solution preserves both your product's integrity and your brand's reputation, making regulatory adherence and operational efficiency achievable without compromise.

Tailored Sanitation Programs for Various Food Facilities

Different food processing operations must address specific regulatory requirements and contamination risks, which means a one-size-fits-all cleaning protocol isn't adequate. It's essential to implement customized solutions that account for your facility's unique operations, crucial checkpoints, and cleaning procedures. Compliance agencies like CFIA and FDA require conformity to sanitation benchmarks, necessitating specialized sanitation and disinfection protocols. By assessing your plant's process flow, circulation routes, and equipment specifications, you can develop cleaning protocols that target critical zones without impeding production. Specialized plans also manage allergen control, contamination control, and residue control, maintaining adherence to standards and product safety. Collaborating with sanitation specialists helps you to implement these tailored solutions, optimize operational efficiency, and preserve your facility's regulatory compliance.

Modern Equipment and Sustainable Solutions

You'll employ cutting-edge technology that maximizes hygiene standards while meeting industry standards. By choosing environmentally safe cleaners, you decrease chemical residues and comply with ecological standards. Execute green waste handling procedures to minimize waste accumulation and strengthen corporate social responsibility goals.

State-of-the-Art Machinery

Professional sanitization demands more than hands-on work; it requires advanced machinery engineered for compliance and efficiency. You require sophisticated cleaning solutions that integrates machinery innovation with systematic management, making certain your facility adheres to strict industry regulations. Professional cleaning units, robotic floor cleaners, and HEPA-filtered vacuums remove pollutants at the cellular level, minimizing risk of cross-contamination. These specialized machines enhance sanitization processes, decrease operational delays, and provide verifiable results through electronic tracking and documentation.

Green Cleaning Products

Although advanced machinery improves cleaning standards, implementing green cleaning products confirms your facility complies with environmental regulations and sustainability goals. You need to choose eco friendly alternatives that satisfy Health copyright and CFIA requirements, ensuring all disinfectants and detergents minimize volatile organic compounds and toxic residues. Choose products approved by recognized organizations, like EcoLogo or Green Seal, to strengthen your commitment to sustainable practices. Install standardized dilution systems to improve product usage and reduce waste, enhancing operational efficiency. Include regular staff training on correct handling and storage of green cleaning agents to avoid cross-contamination and ensure compliance. By prioritizing eco friendly alternatives in your sanitation protocols, you'll both safeguard indoor air quality but also boost your reputation as a conscientious, environmentally conscious facility in Brampton.

Eco-Friendly Waste Solutions

As regulatory requirements for commercial facilities in Brampton continue to evolve, sustainable waste management demands both state-of-the-art machinery and eco-friendly protocols. You need to develop organized waste minimization approaches, utilizing high-efficiency sorting systems and compactors to minimize landfill contributions. Implement source separation processes to enable efficient material recovery, meeting municipal and federal environmental standards. Implement automated collection and tracking technologies to monitor waste streams, maintain records, and facilitate accurate reporting. Adopt eco-friendly solutions, such as sustainable packaging and sustainable storage options, to minimize single-use plastics and hazardous residues. By emphasizing these process-driven approaches, you'll not only meet compliance requirements but also improve operational efficiency. In the end, your commitment to sustainable waste management establishes your facility as a leader in environmental stewardship while meeting Brampton's changing sanitation requirements.

How MWAC Guarantees Consistent Quality and Reliability

Adhering to strict compliance with industry standards, MWAC executes comprehensive quality control protocols and systematic training for all staff to ensure every commercial cleaning project in Brampton fulfills regulatory requirements. You'll benefit from standardized operating procedures (SOPs) that detail exact cleaning methods, chemical usage, and documentation practices. MWAC's quality assurance system utilizes regular audits, real-time reporting, and data-driven assessments to track service consistency and address any deviations immediately. Technicians complete continuous certification in hygiene protocols and safety regulations, confirming they're always up to date with CFIA, HACCP, and GMP guidelines. By utilizing digital checklists and scheduled inspections, MWAC assures each task aligns with regulatory benchmarks. This systematic approach means you can rely on MWAC to achieve dependable, high-standard cleaning outcomes consistently.

Selecting the Right Cleaning Partner for Your Food Facility

Picking a cleaning partner for your food facility requires a comprehensive assessment of regulatory standards, specialized knowledge, and process documentation. You should ensure that the vendor understands food industry cleaning requirements, including HACCP, GMP, and SQF protocols. Examine their operational records—SOPs, cleaning chemical records, and sanitation verification records. Confirm they have expertise managing facility accreditation requirements and can deliver compliance reports for audits. Evaluate their employee development protocols to validate continued proficiency in food safety and contamination control. Don't overlook the significance of traceability; your cleaning partner should maintain thorough record-keeping and corrective action plans. By focusing on these systematic, regulatory benchmarks, you'll obtain a sanitation company who exceeds expectations for your facility's operational standards and safety protocols.

Questions & Answers

What Brampton Areas Does MWAC Cover Outside Food Plants?

Are you aware that over 60% of workplace illnesses can be traced back to? You can rely on MWAC to address this by managing Brampton's office and retail sanitation requirements. Their approach includes planned decontamination, waste stream management, and compliance with provincial regulatory standards. They employ professional-grade tools and eco-certified chemicals, ensuring your facility satisfies occupational health and safety requirements. MWAC's technical expertise reaches far beyond food plant sanitation.

Do You Offer Emergency Cleaning Services on Weekends and Holidays?

If you need urgent cleaning services, you'll find value in flexible scheduling including weekends and holidays to maintain regulatory compliance. You're https://mwaccommercialsanitation.ca/ able to start a service request at any time, and qualified professionals will implement specialized protocols, in accordance with sanitation and contamination control guidelines. This swift response process involves evaluation, control, and cleanup, while adhering to required regulations. By utilizing emergency response capabilities, you preserve operational efficiency and fulfill industry-specific cleanliness requirements, reducing business interruption.

Does MWAC Provide Free On-Site Assessments or Quotes?

You'll be amazed by how comprehensive free assessments are—they're virtually legendary in detailing every safety concern and hygiene issue you might face. When you schedule an premises inspection, you'll get expert technicians who determine regulatory requirements, HACCP protocols, and cleanliness benchmarks. They'll deliver thorough proposals that outline every operation, from initial cleaning to final sanitizing. Stop relying on assumptions—use these assessments to confirm your facility meets even the most rigorous industry requirements.

What Is the Average Response Time for Service Requests?

Upon submitting a service request, you'll find the average service response time usually occurs within 24 hours, showcasing high response efficiency. The process initiates with your inquiry, which is logged and triaged based on urgency and regulatory compliance requirements. You'll receive swift booking confirmation and timeline updates to ensure adherence to industry standards and minimize operational downtime. This systematic process guarantees you meet sanitation protocols while maintaining uninterrupted operations throughout the service lifecycle.

Are Our Cleaners Insured and Background-Checked?

Picture yourself conducting a spontaneous audit and, as it happens, each employee fulfills demanding certification requirements. You'll notice that service personnel aren't just seasoned—they're thoroughly protected and have successfully completed thorough background checks. This process ensures compliance with safety standards and compliance requirements, giving you peace of mind. Companies implement rigorous screening processes, maintaining compliance with professional requirements. You can be confident that all personnel present emphasizes your property's safety and workplace efficiency.

Final Thoughts

Regarding food plant sanitation in Brampton, quality cannot be compromised. Working alongside MWAC, you can be confident that every process follows regulations, from HACCP protocols to allergen control. Their cutting-edge equipment and specialized cleaning plans ensure your facility goes beyond regulatory requirements. Keep your compliance standards intact; depend on MWAC to keep your operations spotless, dependable, and inspection-ready, so you can focus on what you do best: manufacturing safe, high-quality food.

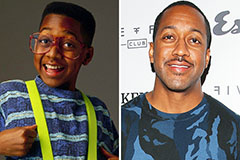

Jaleel White Then & Now!

Jaleel White Then & Now! Tia Carrere Then & Now!

Tia Carrere Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now!